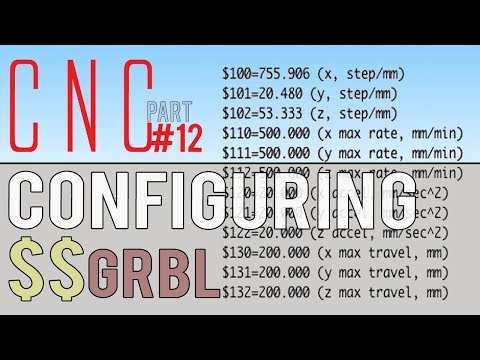

| –ù–∞–∑–≤–∞–Ω–∏–µ | : | First DIY CNC build (part 12) - Configure $$ GRBL on ARDUINO uno TUTORIAL |

| –ü—Ä–æ–¥–æ–ª–∂–∏—Ç–µ–ª—å–Ω–æ—Å—Ç—å | : | 18.30 |

| –î–∞—Ç–∞ –ø—É–±–ª–∏–∫–∞—Ü–∏–∏ | : | |

| –ü—Ä–æ—Å–º–æ—Ç—Ä–æ–≤ | : | 129¬Ýrb |

|

|

Greetings to you dear, thank you for this topic When connecting for the first time, the motors never started, and the driver’s temperature rose The motor took one pulse and stopped working or turning until the order given to it by the program was finished Why didn’t the Nema 17 motor work smoothly and continuously??? Comment from : Muhammad Slwaey |

|

|

Thanks Comment from : Hector Torres |

|

|

Hello, while processing the g-code file I created with UGS in CNC, the CNC axes go to the place they need to go very fast when the carving work of a point is finished and trying to go to a different point (idle acceleration), which causes tooth skipping and the coordinate is distorted I wonder if I need to adjust the grbl settings or the g-code file to reduce the speed of the axes in these transitions (idle speed) Comment from : Beykana |

|

|

Thanks A lot Comment from : Engr M A Kabir Arif |

|

|

How to use 4 ieme axes on grbl? Comment from : Daniel Gauthier |

|

|

Hello,brbrI have built a CNC plasma cutter (MPCNC with GRBL control) and also use it with the Universal Gcode Sende program, but I have the following problem: The file has a length of 100mm, for example, but in reality it cuts me out to 300mm approx All values in UGS are converted to mm (G21) What could be the reason for this and how can I correct this error?brbrPlease send me your feedback as soon as possible!brbrBest regardsbrbrTobias Comment from : Tobias Kittinger |

|

|

Awsom Work bro :) thx for explaining in a very simple way for newbies Comment from : Chris Fernando |

|

|

Nice video, thx Comment from : Szokol Csaba |

|

|

hi Why not show coordenates when move the cnc in universal g code sender ? Comment from : Luiz Farah |

|

|

Can we give a feed rate of 1mm/min using this setup of Stepper motors? Comment from : kunchala bhargav |

|

|

Great video Thanks man :) Comment from : Yoo Projects |

|

|

Dear Willy I'm using CNC laser mini 3018 Pro and after set some program I see that Laser GRBL had lost $ 30,31,32 in GRBL Configuration part So pls help how to get back it Thanks Comment from : 15 - L∆∞∆°ng Gia H√¢n |

|

|

when i press $30 it says error invalid statementbrmy spindle stopped working all of the sudden Comment from : Hamada Ali |

|

|

Dear sir please tell me how to increase speed of CNC machinebr my CNC is running is too slow Comment from : manbhawan furniture |

|

|

Thank you very much Comment from : William Vera |

|

|

Very nice very helpful videoüñí Comment from : under world |

|

|

awesome work! Thank you so much!! Comment from : Prajesh Sanghvi |

|

|

Sir how to provide set home position and home command to each stepper motor Comment from : Sarvesh Amble |

|

|

thank u i am new in the field this video is very good for me Comment from : Magdy Kamal |

|

|

Thank you! Really apreciate it! Comment from : Renato Pierri |

|

|

This is the best video by far for a simple straight forward explanation of this My go to video for reference Comment from : BobbyBoy1962 |

|

|

meget bra takk Comment from : KH Habachi |

|

|

When give g code manualy , error: undefind feed rate How fix this error Comment from : Pradeep Gunarathna |

|

|

why did they take the parameter name away from the $$ list? If it ain't broke don't fix it Comment from : mendebil |

|

|

Excellent Thanks for this Comment from : FPChris |

|

|

Thanks all the best from John in Texas Comment from : John R Pannell |

|

|

what optimum value for speed stepper motor, because when we set to fast the torsion become weak Comment from : Kavlink Tech Channel |

|

|

I think this problem in LaserGrbl v3014 softwear setting brYou can check in above laserGrbl in menu /Grbl/Setting/Jog Control /Grbl/continuos Jogbr on/off Button has side to continuos Jog brMaybe on position is jog work And off position Jog not workbr I will checking at home This time I am in office Comment from : ý§Öý§ïý§π ý§Öý§®ý§æý§Æ ý§™ý§∞ý§Æý§æý§§ý•çý§Æý§æ || akah anam parmatma |

|

|

Controlling parameters disturb for jog function Comment from : ý§Öý§ïý§π ý§Öý§®ý§æý§Æ ý§™ý§∞ý§Æý§æý§§ý•çý§Æý§æ || akah anam parmatma |

|

|

Grbl control (Candle) Comment from : ý§Öý§ïý§π ý§Öý§®ý§æý§Æ ý§™ý§∞ý§Æý§æý§§ý•çý§Æý§æ || akah anam parmatma |

|

|

Yes, alll function is O K, cam program is running, only Jog function is not working, Comment from : ý§Öý§ïý§π ý§Öý§®ý§æý§Æ ý§™ý§∞ý§Æý§æý§§ý•çý§Æý§æ || akah anam parmatma |

|

|

Hi, brMy cnc jog options is not work, brPlz tell me which parameters set in my grbl candle Comment from : ý§Öý§ïý§π ý§Öý§®ý§æý§Æ ý§™ý§∞ý§Æý§æý§§ý•çý§Æý§æ || akah anam parmatma |

|

|

SIR PLZ HELP ME TO CALIBTRATE MY MACHIE Comment from : ramesh chauhan |

|

|

veldig bra informasjon, takk brJeg holder på med en ox cnc, og tenkte å bruke Raspberry Pi 4 med protoneer modul Comment from : Christer |

|

|

I looked the material that your list, five A4988s step motor driver are too expensive for nine dollars on Banggoodcom! wow, I think you spent a lot of money on your work But in China the step motor driver cost less than a dollar and are better DRV8825 than them and step motor for about five dollars

brI plan to make a CNC engraving machine, I think your vedio is very useful, thank you! Comment from : Ming Bian |

|

|

Hellowhat to change on my gbrl settings on LaserGbrl software to achieve 50x50 cm engraving area on laser machineWhen I downloaded Laser Grbl to exchange Benbox I uploaded one hex file as firmwareThis is for some other machine and I have movement 30x30 cmI want 50x50 to have engraving areaMachine which I have is 65x50 3w laser Comment from : firewirehn crnogorac |

|

|

Very helpful video Set up my machine, but just cant get the router motor to start! Comment from : vedulji |

|

|

Hello, I'm mounting my cnc machine following your videos How do you calculate the $100, $101 and $102 values? thanks!! Comment from : Urko Fern√°ndez de Retana |

|

|

Very helpful, clearly explained, thanks! Comment from : Greg Woolley |

|

|

Thank you Best regards Comment from : Miguel Gois |

|

|

How can I increase the speed rather than using codes like $110 $111 any other method? Comment from : Abrar Muqheeth |

|

|

This helped me out Thanks for posting! Comment from : Mike G |

|

|

hello can you help me ,i have axis problem ,the maximum limit of my Y axis is 58mm ,i enabled soft limit , i start to move Y axis from 0 , but it move only -58 , alarm comes when I tried to move on positive direction ,how to solve this ,i also invert axis direction but i won't work if soft limit is enabled,it work only when soft limit is disabled Comment from : Kvamsidhar Vamsi |

|

|

I installed limit switches And when it is pressed motor stopped working but after that I need to restart everythingand it's not accepting any further commands is there any option to move the axis away from the limit switch automatically after it is pressed Comment from : Vishakha Srivastava |

|

|

what about setting soft limits and home? Comment from : needsbeermoney |

|

|

Can I set backlash in this software Comment from : Arsad Khan |

|

|

How to fix Z axis to 0 Comment from : DJL |

|

|

hello this configuration is valid pear NEMA 23 Comment from : tazmahv lucky |

|

|

Thanks Mr Willy,that's very helpful as always,I have question about the values of $110-$112,how would you know the values to set ? is it based on trying or based on calculation? Comment from : Abdo Ale |

|

|

Any videos for diy Arduino cnc plotter ? Please Comment from : Vishal Gaurav |

|

|

is this setting written by me ? or it's written by the same program? Comment from : سنارات ملونه |

|

|

Hello sir brI used universal sender but i browse small gcode than is work properly but i download some g code like image but after browse universal send show empty file and show just complet 000000 sec plz give solution plz sir Comment from : VS Top |

|

|

how can I set up the core XY configuration? and how can I add a servo on the pen and control it with the UGS Comment from : jonathan sidon |

|

|

HellobrbrYou told here (Video Minute 4:18) from the limit switches and that you come back to these in a lter VideobrDoes this information about using limit switches with the arduino exist in one of your Videos?brI doesnt find there it in you Videos! Comment from : MiJabe |

|

|

thank you for the explanation i would like to know how you did the homing and the point zero with grbl and arduino and hw you calculate the step per revolution of your motor i have the nema 23 Wantai stepper motor model 57BYGH115-003B 428 oz Step Angle: 18 degreebrbrVoltage: 63VDCbrbrCurrent: 3 A/phasebrbrResistance: 21Ohm/phasebrbrInductance: 9mH/phasebrbrHolding torque: 30Kg-cm 428oz-inbrbrRotor inertia: 810 g-cm2brbrDetent torque: 089 kg-cmbrbrNumber of wire leads: 4 how can we calculate the step per revolution Comment from : user new |

|

|

Is acceleration that slow really necessary? I have not yet set but I'm wondering if setting mine to 200 would be bad It's a 4mm pitch per rotation lead screw, and if I stall the motor, even at full speed the weight of the gantry can't move that lead screw Comment from : Eugen Krause |

|

|

nice job :) i'm doing the same with my cnc :P Comment from : CottenJet |

|

|

Sir,Please snd the download link of universal gcode sender Comment from : Anuj Kumar |

|

|

Direction error Comment from : Maathav Rajan |

|

|

Hi, friend!! Excelent tutorial!! Just one question: why my Arduino don't save the parameters? I'm using grbl controller 361 Comment from : Christopher TreCe |

|

|

Thanks lad ;) Comment from : Ben Frawley |

|

|

Hibri'm working on DIY cnc router project but i have a problem with lead screw or ball screw it's expensive man i spent about 650$ for stepper Nema 34 and other stuffbrThe question is Do you think if i use a belt my machine will be fast or what ?? Comment from : Hannibal Bianchi |

|

|

Awesome Video Series - Thanks for sharing this I'm strongly considering building one and this is extremely helpful and really inspiring Comment from : The Mindscape Channel |

|

|

Man, I just learned everything I was wondering about my new GRBL cnc firmware Well, done, thanks Comment from : Jess Hugh |

|

|

you are great Comment from : Azeem khan |

|

|

thank you for this video can you show us on a video the wiring of the micro switches N/O on the GRBL shield and how to male the setup on the software Comment from : user new |

|

|

May ask for help for Indonesian language I really need this way Comment from : New Syah Ne Kanca Ne |

|

|

Thanks so much Willy I now have to go back through all your videos and get a complete understanding before I embark on this journey Are you able to do a video on samples or items you have been able to created with this machine Comment from : Jean-Noel Seneque |

|

|

Thank you! Very clearly shows the importance of each activity I think it will be useful for many beginners Comment from : Toto |

|

|

Brilliant Mr Willy! I just connected my first stepper to my machine as a test and its agonizingly slow! How do i fix it? Why just watch Willy's CNC part 12 of course! Thanks again for making it so easy! Comment from : Chris comeau |

|

|

Thanks Mr Willy,that's very helpful as always,I have question about the values of $110-$112,how would you know the values to set ? is it based on trying or based on calculation? Comment from : Mohamed Amine BIDA |

|

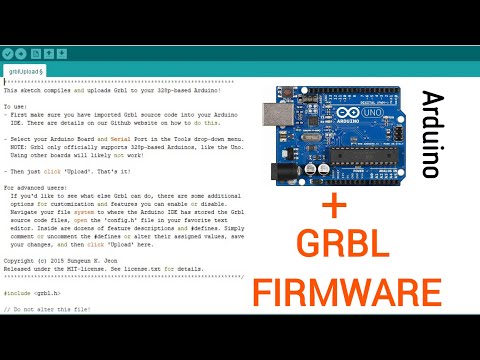

Setting up GRBL on Arduino Uno for CNC –Ý—ï–°‚Äö : Arnov Sharma Download Full Episodes | The Most Watched videos of all time |

|

CNC 3018 PRO Laser Engraver Wood CNC Router Machine GRBL ER11 Hobby DIY Engraving Machine –Ý—ï–°‚Äö : Newswan Tool Download Full Episodes | The Most Watched videos of all time |

|

How to operate GRBL CNC Machine | loading grbl + generating gcode + calibrating axis –Ý—ï–°‚Äö : Mr Innovative Download Full Episodes | The Most Watched videos of all time |

|

Setting GRBL CNC || Pemesanan Mesin CNC 085707725856 –Ý—ï–°‚Äö : Syukron Eko Prasetyo Download Full Episodes | The Most Watched videos of all time |

|

Install GRBL firmware in Arduino | CNC tutorial ‚è© –Ý—ï–°‚Äö : Quick Look Download Full Episodes | The Most Watched videos of all time |

|

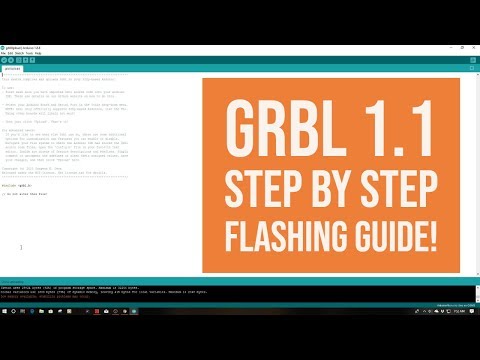

GRBL 1.1 - Step By Step Installation Guide to Flashing Arduino Uno! –Ý—ï–°‚Äö : DIY3DTECH.com Download Full Episodes | The Most Watched videos of all time |

|

GRBL with Arduino CNC Shield ‚Äì Complete Guide –Ý—ï–°‚Äö : DIY Engineers Download Full Episodes | The Most Watched videos of all time |

|

How to Control Stepper Motors with Arduino using a GRBL CNC Shield! –Ý—ï–°‚Äö : LeMaster Tech Download Full Episodes | The Most Watched videos of all time |

|

Arduino CNC Shield Tutorial - Control Stepper Motors using CNC Shield V3.0 –Ý—ï–°‚Äö : Superb Tech Download Full Episodes | The Most Watched videos of all time |

|

Sainsmart 3018 PROVer Cnc. Candle, Grbl u0026 Axes Calibration Tutorial. Part 2. –Ý—ï–°‚Äö : techydiy Download Full Episodes | The Most Watched videos of all time |