| –ù–∞–∑–≤–∞–Ω–∏–µ | : | DIY Cheap Arduino CNC Machine - Machine is Complete AND Accurate! |

| –ü—Ä–æ–¥–æ–ª–∂–∏—Ç–µ–ª—å–Ω–æ—Å—Ç—å | : | 24.14 |

| –î–∞—Ç–∞ –ø—É–±–ª–∏–∫–∞—Ü–∏–∏ | : | |

| –ü—Ä–æ—Å–º–æ—Ç—Ä–æ–≤ | : | 1,8¬Ýjt |

|

|

Please make an update to this Comment from : Michael R |

|

|

Talent & handsome Comment from : ý∏Ñý∏∏ý∏ìý∏ûý∏µýπà ý∏Ñý∏∏ý∏ìý∏ûý∏µýπà |

|

|

I'm back again bro I watched another video from another content creator with this subject and he went deep into the electronics side of things which is so hard to find others doing the same Most ppl gloss over the electronics but what they don't realise is this is the part most of us newbies really struggle with and would very much appreciate u guys help out her with some indepth videos on the set up and wiring and not just show a diagram and sdpeed up the video to 25X's normal speed LMAO I hope u don't take my comment the wrong way my dude but it needs to be said now and again Comment from : SLIMS BOXING COMMENTARIES |

|

|

Good project thanks Comment from : Grant Smith |

|

|

Don't cut it smaller It's always better to be bigger I built a 4x4 cnc plasma cutter and wish it was 4x8 Comment from : Keith Wright |

|

|

srsly,this trash cant be accurate under pressure Proving it with a fucking penman, they must have paid you alot this is the last time i watch you going down from an interested guy, willing to learn, to a sellout idiot with no plan of cnc manufacturing unsubscribed Comment from : Bollerkotze |

|

|

I’ve made at least 3 maybe 4 of these after having so many 3D printers laying around and wanting to use the motors I’m gonna tell you right now save your money and just buy a legit cnc These are great for learning but not rigid enough for anything serious What I’ve found is even a shitty machine can do a good job with the right spindle so if you do go this route don’t cheap out on the spindle Get a nice 2kv VFD spindle with water cooling Also buy good endmills Comment from : Chucky Gibbs |

|

|

I would love to build one that could draw on a 22"x17" sheet of paper I wonder how much it would cost to build? Comment from : Frank Hiatt |

|

|

Hi Comment from : shn |

|

|

I know this is five years old but it's timely for me as I build a CNC plasma cutter using Arduino and GRBL Thanks John! Comment from : David Wrate |

|

|

youtube/cq9K-jdPugg watch and subscribe my channel to improve creativitythank you Comment from : supun asanka |

|

|

WOW WOW AMAZING THANK YOU A LOT THANK YOU Comment from : Saber Cruiser |

|

|

Exelente video You are a robóticas type of guy wanna be whilst I am a machinist type of guy wanna be We all have a bit of that, i hope :p Comment from : Daniel Rosales |

|

|

rewatching this series of vids now that i finally built my first cnc machine you are the reason im here today well you and this old tony Comment from : Q5Grafx |

|

|

can't find the first video!! Comment from : Joe Mata RC |

|

|

To simplify Xaxis accuracy dual the drivetrainbrYaxis seems very compact all goodbrZaxis and Raxis and Baxis are missing components, not shown herein Comment from : Kenneth Kustren |

|

|

Hi there, thanks for your nice video I want to make little project with 2 axis Cnc systembrHow can you help me? My project same like centre lathe My requirement is one axis with high torquebrSpindle chuck with low rpm 10 - 250 rpms Second axis is ball screw for cross slide moment forbrVariable pitch purpose Both axis I want servo motors with gear reducer for high torquebrPlease suggest me one of best option controller system with full accuracy and mechanismbrThanks Comment from : Gurudan Singh |

|

|

whats the pricepoint? Comment from : micronomeful |

|

|

Thanks for showing the calibration, excel spreadsheet, etc! Comment from : BinarySpike |

|

|

This is so cool Comment from : Alexander C |

|

|

If there is one video out there that can convince someone that it is not hard to build a cnc for hobby use, it is this one I like the fact that the cost of the individual parts is spelled out - as well as the limitations one has with these parts Comment from : Stelios Posantzis |

|

|

If possible to make guitar strings making machine Comment from : venko sha |

|

|

CNC HOT HIREbr youtube/BvJrHP0nzBs Comment from : ADEMIR GOMES TUPÃ |

|

|

Holy crap you just invented something, But what should we call it ? Pen picture drawing apparatus? No Pen printer? No Pen Plotter YES!! PEN PLOTTER!!!! Actually what is funny is these DIY CNC were started by modifying Pen plotters and printers We have come full circle lol brbrAny rule of thumb for sizing the right stepper or servo motor for the weight it will be driving ? I’d like to build a router that can cut 4’x8’ sheets Comment from : Reno Simpson |

|

|

How did you get the grbl into inches instead of mm? as of now I have to use g20 at the beginning of my code Comment from : Adam Nagy |

|

|

very cool and so fun I actually did exactly the same thing when i set up my little plasma cuter table as a test before i had the cutter hooked up i mounted a sharpie and drew on some cardboard! Comment from : Chris Graham |

|

|

Dear sir,Hi there to all @NYC - CNC,I was following ur this project almost since 2year and was able to assemble this 2d plotter after about year and half backsir,I am a science graduate with chemistry as major but having aptitude for mechanicspls let me know yr e mail adress so I can send u video of my cnc machine made as per your videolet me tell u that I am a retired enggof 73yrs made this cnc just to know how cnc machine worksin future I intend to assembled Table top cnc router for my carving hobbythanks a lot for your video and u and your team at NYC-CNC Comment from : MAHESH M JOSHI |

|

|

Not sure if you still reply on here 4 years on but Do you have that spread sheet you use to calculate distances etcbrPlus what we're the alternatives to the universal G Code sender program that have found over the years?? Comment from : Andy Taylor |

|

|

its only good for cheap 5w laser modules Comment from : Anna Paulinovna |

|

|

Good video Comment from : Nora Hung |

|

|

Great details! Comment from : Bobby Shaftoe |

|

|

70 dollar machine 2000 dollars to hold itü§£ (joking love your videos) Comment from : trialnterror |

|

|

It is very good project But please kindly explain how to run small cnc program, how to home the machine Comment from : Kaushal Kumar |

|

|

I'm a welder but have a deep interest in building my own machines This is a great resource! Thank you ver y much for the information you provide!!! Comment from : Cody Fale |

|

|

Sir we can this machine for A1 paper size Comment from : HOW TO MAKE GARMENT PATTERN |

|

|

what is the budget for this? Comment from : Mister p |

|

|

I'm very shocked to hear a machinist say that he isn't worried about all the slop that is in that set of rails, you can mic that all day and I guess I'd say it may be ok as long as your only going to usi it for laser engraving, but as soon as you mount a motor on that and as soon as it starts a cutting process the tourque & resistance are going to mess any piece they try to cut even if they are only milling a thou or two at maybe 5 mm a minute, unless you planning on cutting foam and balsa wood if the people your selling this to are planning on being able to use it on metal, & don't realize that they are going to have to run it at 5mm a minute or less in order to keep it from destroying any piece of work they put on it Especially if you making this to use on metal, as much slop as it has it would probably not be very accurate on dense foam over an inch thick Comment from : 3Mars-tons |

|

|

I just love people who help others! Thanks a lot man!! Comment from : Shereif Wagdi |

|

|

he clicked on Don‘t Save 19:43 Comment from : MeLLoWBaBy |

|

|

Love your passion Comment from : Omar Cusihuaman |

|

|

I would have used threaded rods instead as the problem compared to printers for a cnc is that it may disturbe the motors when as for example engraving due to non linear movement in directions of the drillbits Thats why a nema 23 wich has more holding torque does the job a bit better, the 17 can do it very well but they dont have the mass in the shafts to even out lets say vibrations, bumps etc Comment from : Jon jonsson |

|

|

because of your videos i just bought a 3 axis 3040 if i told you what i got it for youd never believe it in a million years but at the end of the build it will be a 5 axis for just about $250 well maybe 300 ill have to purchase a 5 axis controller i have been 3d modeling since 1991 so that part of fusion 360 was easy but learning the ins and outs of g code is the next step Comment from : Q5Grafx |

|

|

Thanks! Comment from : george park |

|

|

You should add extra braces to get that wiggle out of the axis just 2 stiff pieces of metal bolted to the top will fix that Comment from : excited box |

|

|

awesome Comment from : Markiss Boi |

|

|

Cool little toy I couldn't help but think about the large industrial Multicam precision CNC gantry routers which this is a mini replica of It you added an additional stepper and pulley system to the opposite side on X, you'd have something there that would greatly improve speed, accuracy and rigidity along X Although the Multicam's are using steppers with gears on racks, the drive belts and pretty rigid for amatuer home use Check their stuff out Overpriced, but they have a lot of capability wwwmulticamcom/ Comment from : Prey Mantas |

|

|

Leave the x long and install a tool changer Comment from : Brandon Edwards |

|

|

So how much does the entire thing cost? Comment from : Danny Boy |

|

|

as soon as you actually start selling these kits, please sign me on Comment from : Safe Crackers Inc |

|

|

5:41 dog passing by wearing a jacket, lol Comment from : gen kidama |

|

|

I'm not sure if this will get to you but I love your videos and stumbled upon this I was wondering if you would revisit this with all that you have learned since doing this video or do a video on the pros and cons of the many diy CNC machines out there like the MPCNC Comment from : Jason G |

|

|

Man you have no idea I was setting up to buy ballscrews, going to use timing belts now Thanks for the save! Comment from : davy nolan |

|

|

Great work , i did the subscription hoping i understand cnc more üëç Comment from : Marine GE |

|

|

not sure how i mist this first time around ?? Comment from : Stormbringer Mornblade |

|

|

When can we see some more of that rotary engine Comment from : MFL Manufacturing |

|

|

hi NYC CNC to learn work with a arduino cnc machine it is simular with fool size cnc mashine? i mean it has simularities? Comment from : Mindaugas Berteska |

|

|

The 2-4-6 blocks threw me -- thought I was looking at some sort of weird forced perspective thing Comment from : Alyosha |

|

|

You are the best bro✌️ Comment from : Tony Ziadeh |

|

|

What is the cost of this machine? Comment from : raj chitrashala |

|

|

tco/gYUKPGsFw0?-homemade-router-table 7464 Comment from : ellsa |

|

|

I dare you -> " water jet cutter with arduino" Comment from : ahmad maulana |

|

|

so basically you made a printer can this diy build do anything besides draw a picture? theres printers that are 20 to 30 bucks that allready do this to the the cost you basically made a very over priced printer right? Comment from : News Now Fort Worth |

|

|

If you want to try the next step in open source cnc grbl controllers, have at wwwkickstartercom/projects/2118335444/automate-anything-with-super-gerbil-cnc-gcode-cont Comment from : Paul de Groot |

|

|

Could this be useful as a CNC plasma cutter? Or at least a laser cutter? Comment from : Bwayne Powa |

|

|

what if I use 6mm diameter rods, is there any problem? Comment from : Sto_Karfi! |

|

|

Did you Ever use that bell everman low boy with the Clearpath? Comment from : Nerdly |

|

|

"ùêàùê≠'ùê¨ ùêãùê¢ùê§ùêû ùêö ùüëùêÉ ùêèùê´ùê¢ùêßùê≠ùêûùê´ùê´ùê´ùê´ ùêüùê®ùê´ ùê∞ùê®ùê®ùêù" ùêÉùêàùêò ùêàùêßùêØùêûùêßùê≠ùê¢ùê®ùêß ùêìùêÆùê´ùêßùê¨ ùêö ùêëùêûùêÝùêÆùê•ùêöùê´ ùêèùê¢ùêûùêúùêû ùê®ùêü ùêñùê®ùê®ùêù ùêàùêßùê≠ùê® ùêÄ ùêÇùê®ùêØùêûùê≠ùêûùêù ùêñùê®ùê´ùê§ ùê®ùêü ùêÄùê´ùê≠ >> tco/gYUKPGsFw0?1dda23juhe65aa 4931 Comment from : Taryn Perez |

|

|

Garble? Comment from : Neonblue Industries |

|

|

"ùêàùê≠'ùê¨ ùêãùê¢ùê§ùêû ùêö ùüëùêÉ ùêèùê´ùê¢ùêßùê≠ùêûùê´ùê´ùê´ùê´ ùêüùê®ùê´ ùê∞ùê®ùê®ùêù" ùêÉùêàùêò ùêàùêßùêØùêûùêßùê≠ùê¢ùê®ùêß ùêìùêÆùê´ùêßùê¨ ùêö ùêëùêûùêÝùêÆùê•ùêöùê´ ùêèùê¢ùêûùêúùêû ùê®ùêü ùêñùê®ùê®ùêù ùêàùêßùê≠ùê® ùêÄ ùêÇùê®ùêØùêûùê≠ùêûùêù ùêñùê®ùê´ùê§ ùê®ùêü ùêÄùê´ùê≠ >> Woodcarvingmachineeblogspotcom 3208 Comment from : Benton D Simmons |

|

|

I haven't watched such video that including patient and detailed introduction to cnc machinesThank you! Comment from : Phoebe Yang |

|

|

Any of those Patreons want to help this poor guy by giving those CAD files? Comment from : Umair Ahmadh |

|

|

üò±üò± DIY how to create a CNC using Arduino üò±üò±br wwwingeimaksit/1cnchtml Comment from : Ingeimaks |

|

|

ùóßùóµùó≤ùóøùó≤ùó≤ùó≤ ùó∂ùòÄ ùóÆùóπùòÄùóº ùóÆ ùó∞ùóªùó∞ ùóØùòÇùó∂ùóπùó±ùó±ùó±ùó± ùó¥ùòÇùó∂ùó±ùó≤ ùóºùóª > Woodcarvingmachineeblogspotcomar Comment from : Dolll er |

|

|

How much it costs Comment from : be mine |

|

|

Really informative thankyou buddy Comment from : Taieep Unter |

|

|

Thanks for great video, brCan we make injection mould with this machine ?, brWhat cheap and best machine suggested to make mould? Comment from : Piyush Verma |

|

|

wery naise your brain ant warking,video ,speeche bram happy o waching thios videobrsooper Comment from : Althu electronics |

|

|

cool Comment from : Frankies CNC & Woodworking channel |

|

|

Didn't see if someone already suggested thus You're using toothed belts and pulleys? Why not measure the distance per tooth on the belt (maybe count a number of teeth, take total distance and divide to get distance per tooth) With that and the number of teeth on the drive pulley you should have a good measure of distance per motor revolution Comment from : Mark Nahabedian |

|

|

Great video ! is there a way to download that excel sheet ? thank you Comment from : adrianclaudiu90 |

|

|

Would this be abble to upscale to about 15meters by 25 meters Comment from : Daan Kouwen |

|

|

too fancy your cnc its not cheap at all, your using 4 steppers for x and y and your not using the up and down z, instead of only 3 steppers for x,y, z Comment from : Andreas Christodoulou |

|

|

please email me the document on how you build this arduino cnc machinebremail is t2lethiwekhuzwayo@gmailcom Comment from : Letha Khuzwayo |

|

|

Which method of motion is the most accurate screws or belts? Comment from : Mr Me |

|

CNC 3018 PRO Laser Engraver Wood CNC Router Machine GRBL ER11 Hobby DIY Engraving Machine –Ý—ï–°‚Äö : Newswan Tool Download Full Episodes | The Most Watched videos of all time |

|

Arduino CNC Shield Tutorial - Control Stepper Motors using CNC Shield V3.0 –Ý—ï–°‚Äö : Superb Tech Download Full Episodes | The Most Watched videos of all time |

|

Best Website For: Cheap VPS, Buy Cheap VPS For Forex Trading, Cheap Windows VPS –Ý—ï–°‚Äö : SabiMentors - Osazee Kelvin King Download Full Episodes | The Most Watched videos of all time |

|

GRBL with Arduino CNC Shield ‚Äì Complete Guide –Ý—ï–°‚Äö : DIY Engineers Download Full Episodes | The Most Watched videos of all time |

|

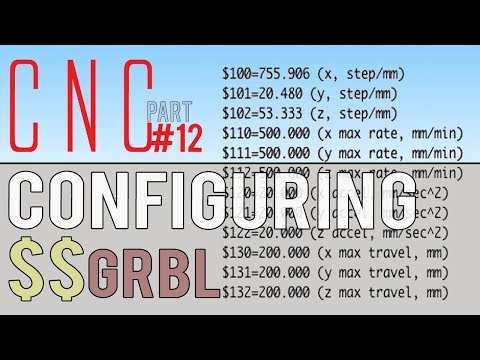

First DIY CNC build (part 12) - Configure $$ GRBL on ARDUINO uno TUTORIAL –Ý—ï–°‚Äö : WillysGarageNorway Download Full Episodes | The Most Watched videos of all time |

|

Cara Hitung Step per mm CNC atau 3D Printer - 100% PRESISI || Calculate Step/mm CNC or 3d Printer –Ý—ï–°‚Äö : botak 333 Download Full Episodes | The Most Watched videos of all time |

|

Setting GRBL CNC || Pemesanan Mesin CNC 085707725856 –Ý—ï–°‚Äö : Syukron Eko Prasetyo Download Full Episodes | The Most Watched videos of all time |

|

X-ray machine camera New version X-ray machine heavy quality pictures 60 kva portable machine –Ý—ï–°‚Äö : X-ray Vlogs Download Full Episodes | The Most Watched videos of all time |

|

Setting up GRBL on Arduino Uno for CNC –Ý—ï–°‚Äö : Arnov Sharma Download Full Episodes | The Most Watched videos of all time |

|

How to Control Stepper Motors with Arduino using a GRBL CNC Shield! –Ý—ï–°‚Äö : LeMaster Tech Download Full Episodes | The Most Watched videos of all time |